Keep It Contained: Common Mistakes in Drain Protection

Why Drain Protection Matters for Businesses and the Environment

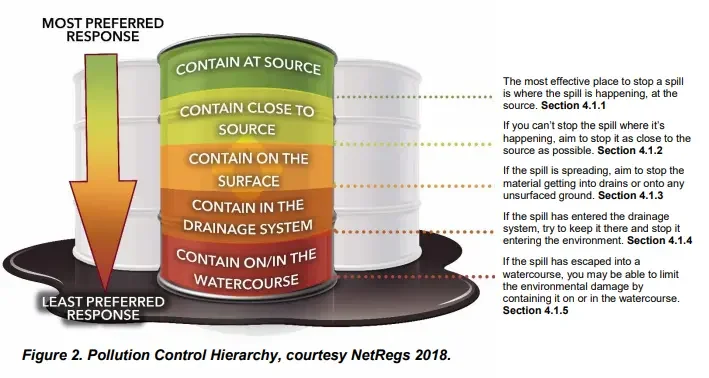

Image taken from - GPP 22 Dealing With Spills

Introduction

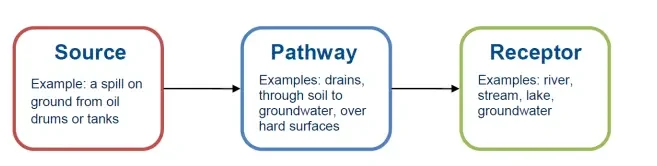

Imagine this: a sudden spill of oil or chemicals, and before you have a chance to think, it’s already flowing towards the nearest drain. What seems like a minor accident can turn into a significant environmental incident in mere moments. Drains, designed to swiftly remove rainwater from your site, can also serve as pathways for contaminants to reach rivers, lakes, controlled waters and the groundwater. The source – pathway – receptor model states you need all 3 to have a risk of pollution. Companies can never remove all sources of pollution, and receptors will always exist downstream so removing the pathway is usually what is required to break the chain. That is why having effective control measures on site to be used both proactively and reactively is so important.

Image taken from - GPP 22 Dealing With Spills

This month we have conducted training for 2 new clients, both clients had previously had a “professional” site survey undertaken by spill control product companies, and yet, despite ordering what was advised, neither site could effectively protect their drainage.

The first site had predominantly aco channel drains installed, with several 45 x 45cm gullies around the site in medium risk areas. However, the only drain protection they had was one 500 x 50cm neoprene drain cover. Each aco drain on site was longer than 5 metres and so this drain cover would not allow the site to effectively isolate any of the drains on site. The drain mat was listed in the site’s procedures but had never been tested in a drill situation to confirm that the site could control a spill in an emergency. Because of the way the drainage congregated on site we recommended purchasing a drain closure device to be used in the final manhole on site. We also recommended purchasing single use clay drain mats to seal the gullies.

The second site also had a mixture of aco drains and standard gullies on site, however they had been sold the opposite mitigation. This site only had 65 x 45 cm drain mats on site. The site had 4 of these drain mats, despite only having one standard gully on site. Furthermore the 4 mats they had were all stored in the front yard, when the only suitable gully for their use was in the rear yard. Meaning they would have to travel across site and back again before they could deploy the drain mat. We again recommended the only way to seal the aco drains was to isolate the drainage in the downstream manhole. We also recommended that they should move the existing clay drain mats into the rear yard.

We often see that drain protection measures are inadequately specified, sometimes by companies in the spill industry who should not be making these mistakes. Drain protection should not be a tick box exercise. It needs to be specified based on the types of drainage, the flow/fall of the catchment area, the risks within the catchment area and the downstream receptors to give staff the best chance of protecting drains effectively. Furthermore, drills should be run to test the efficacy of the products which have been specified. Simulations using water can give a good indication as to whether the drain protection measures on site will work in an emergency situation.

Options for protecting drains

The spill control hierarchy as shown below gives information on the preferential order of controlling spills. In an ideal world the spill would be avoided or have secondary containment to prevent the spread, however we will jump straight in to “Contain on the Surface”.

Contain on the surface

There are multiple options for sealing spills on the surface each have their own strengths and weaknesses. The most common options are:

Mechanical drain seals – Mechanical drain seals are the most expensive option, however, of the reusable systems they are also the most effective. These systems clamp onto the drain and have a neoprene sponge seal which compresses to the ground making a watertight seal.

PROS – Reusable and very effective.

CONS – More expensive than other reusable systems.

Single use Clay drain mats – Single use clay drain mats are probably the most effective system when properly deployed. These drain mats are made from a clay substance which remains malleable. This means that these mats fit the contours on and around drains to form an effective seal, even on uneven or broken drains. They are not the easiest units to use especially if you have not had training. They are single use only and have a 3 year shelf life before they need replacing.

PROS – Very effective on a range of drain sizes and on drains in a poor condition.

CONS – Single use, need replacing every 3 years even if unused, take longer to deploy than other systems.

Reusable neoprene – The cheapest but least effective option, and not one we recommend. These units can be rolled out over drains including channel drains. The construction from neoprene means they are lightweight and quick to deploy. However they do not mould to the shape of the drain or adhere themselves to the drain cover meaning a watertight seal is rarely achieved.

PROS – Cheap, reusable and suitable for channel drains.

CONS - Ineffective

Reusable polyurethane – Polyurethane drain mats offer a more effective alternative to the neoprene drain mats. They are thicker and more robust and come with a sticky side which adheres to the drain cover. This gives a better seal than the neoprene covers, but isn’t always watertight. However the sticky side will also pick up debris/dirt which makes it less effective over time/after several uses.

PROS – Cost effective reusable option

CONS – Not always watertight and loses efficacy over time

Reusable magnetic – Similar in price and effectiveness to the polyurethane drain mats. These magnetic units adhere through magnetism to the drain cover and form a good, but often not watertight seal. Unlike the Polyurethane covers they do not pick up dirt/debris and can be wiped clean.

PROS – Cost effective reusable option

CONS – Not always watertight

If your site is set up so that the above options are effective then containing on the surface is the best option. Once you have allowed spills to enter drains you lose sight of them and even with downstream mitigation are relying on the drainage to be watertight. Broken/cracked drains will allow pollutants to leach out of the drain and pollute the ground/groundwater on site. However many sites will struggle to effectively seal drainage to keep the contaminants out of the drain, in which case you will need to contain the spill in the drain.

Contain in the drain

Containing spills in the drain is a very effective way of protecting the environment. A lot of sites will have interceptors installed which only protect against oil spills, but strangely it is far less common to see drain closure devices installed which can prevent all contaminants leaving site such as oils, chemicals and foodstuffs.

Fixed closure valves - Fixed closure valves such as flapstoppers can be installed into manholes downstream of pollution risks. They can be used proactively at high risk times or when a spill occurs which enters the drains, they can be activated by the push of a button sealing the drainage in a matter of seconds. They can also be linked to a range of sensors e.g. oil, pH, fire alarm to automatically activate if they pick up an issue, even if no one on site has realised the spill has occurred. With the spill contained on site a tanker can remove the contamination and clean the drains to remove any residues.

PROS – Very effective, quick to operate, can have automatic activation set up

CONS – More expensive than other options, not portable.

Manual Penstocks – manual penstocks are similar to Flapstopper systems, but are a manual system. The penstock is installed in a manhole chamber and a key above ground is used to activate a sluice gate which drops into the drain line. They can be used proactively and reactively, however they do not have automatic activation. They are a more cost effective option than the flapstopper but are slower to activate.

PROS – More cost effective

CONS - Slower to activate and are not automated.

Portable drain bladders – Portable drain bladders can be used as a cost effective option of blocking drains. Because they are portable they can also be used on sites with multiple discharge points. They are inflatable bladders which can be deployed into drains using a lance/telescopic pole (avoiding Confined Space Entry), once in position they can be inflated using a pump on the surface to block the drain line.

PROS – Most cost effective option and can be used in different locations on site.

CONS - Slower to activate and not as robust as other units.

Best Practices for Businesses

Training and Awareness

Educating staff about the importance of drain protection. Regular training ensures that everyone knows how to deploy blocking devices and respond quickly if a spill occurs.

Spill Response Planning

Develop a spill response plan that includes clear instructions for blocking drains as a priority in the event of a spill. Make sure drain covering equipment is easily accessible and regularly maintained.

Routine Maintenance

Inspect and clean drains frequently to ensure they aren’t already partially blocked with debris, which can worsen the impact of a spill. Regular maintenance also helps identify potential problem areas before an emergency arises.

Proper Storage and Handling of Materials

Store chemicals, paints, oils, and other hazardous materials away from drains and in secure containers. Use secondary containment systems to catch leaks before they can spread.

Reporting to Authorities

Spills which have left site need to be reported to relevant authorities such as Environmental Regulators (EA, NRW, SEPA NIEA) and Sewerage Undertakers. You should also liaise with the local fire and rescue service to discuss your drain isolation preparedness.